Next evolution of Aircore EC motor delivers higher levels

of efficiency, power and torque density in a smaller, lighter form factor with

features for easier installation and service

CHICAGO

– Jan. 22, 2024 – Today at the AHR Expo, Infinitum, creator of the

sustainable air-core motor, unveiled the next generation of its award-winning Aircore EC, a high-efficiency motor

system designed to sustainably power commercial and industrial applications,

such as HVAC fans, pumps and data centers with less energy consumption, reduced

emissions and reduced waste.

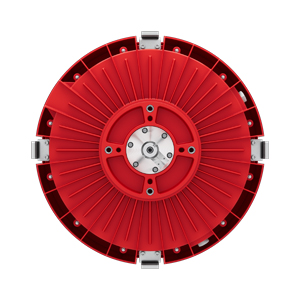

Infinitum’s latest generation Aircore EC motor

system features an integrated variable frequency drive and delivers upwards of 93%

system efficiency, as well as class-leading power and torque density in

a low-footprint package that is 20% lighter than the previous version, with new

features for easier installation and serviceability. The Aircore EC motor

system is available immediately in four standard frame sizes ranging from 3-15

HP at 415V, 460V and 575V for the Canadian and US markets. In addition, Infinitum will be releasing a heavy-duty version of the

Aircore EC suitable for pump and more demanding fan applications.

Additional features of the Aircore EC motor

system include:

●

Custom Nameplating: Allows customers to match

an application’s exact HP/RPM specifications for reduced energy, electrical and

wiring costs

●

Flexible Mounting: Compact form factor enables

a variety of horizontal, vertical and peripheral mounting options

●

Controls: Optional IoT capabilities and Infinitum’s

I-con motor control software

ensure continuous monitoring and reporting of carbon emissions, energy

consumption, heat and vibration for optimal energy management, performance and

predictive maintenance

●

Communication: Support for a wide variety of

communication protocols, including MODBUS RTU, Analog, MODBUS IP, BACnet MS/TP

and more

●

Serviceability: User alerts identify specific

problems for faster resolutions; removable access panel allows for easier

access to terminals, connectors and programming ports

“Infinitum’s

Aircore EC product is unique in the industry and opens design possibilities for

a wide variety of use cases. Its compact form factor enables direct mounting

options which can limit additional cost associated with installation,” said Blake

Griffin, analyst, Interact Analysis. “In addition to achieving IE5 efficiency,

Infinitum’s custom nameplating capability is an extremely powerful offering as

it can drastically lower overall capital investment associated with large motor

driven systems. This benefit cannot be understated when considering

installations of motors can reach the hundreds or thousands in projects within

sectors like data centers and commercial buildings.”

“Infinitum’s Aircore EC motors are a key

component of our APL-DP-EC Series of plenum fans for air handling units, which

are recognized for their space and energy savings and commonly used to cool

data centers,” said Don Barkley, HVAC Sales Manager of Canarm. “Infinitum motors can

be used to build fan arrays that offer high-reliability and redundancy for data

centers, while the motor’s modular design requires less labor for installation

and allows for easier maintenance. We look forward to taking advantage of the

latest features in this new version of Aircore EC.”

Infinitum’s

technology was recently highlighted in the 2024 Global Cleantech 100 report

for its ability to achieve deeper building decarbonization by boosting the

efficiency of HVAC hardware that is enhanced by the motor system’s software to

allow for granular control and preference-setting.

“Designed

with a greener future in mind, the next evolution of our Aircore EC motor

system pushes the boundaries of efficiency and sustainability even further,”

said Ben Schuler, founder and CEO, Infinitum. “The combination of lighter

materials, higher efficiency and power density, and design for serviceability

and reusability give our new Aircore EC motor the advantage to power the

world’s most energy-intensive applications with less energy, emissions and waste.”

The

Infinitum Aircore EC motor replaces the heavy, copper wound iron stator found

in traditional motors with a lightweight, printed circuit board (PCB) stator

that is 10x more reliable. When compared to conventional motors, it is 10-65%

more efficient, 50% smaller and lighter, and uses 66% less copper. The motor’s

modular design allows for housing, rotors and stators to be reused multiple

times to serve future generations. The Aircore EC motor

system is covered by 43 issued patents and 48 pending patents and IP-65 rated.

To

learn more about Infinitum’s latest generation Aircore EC motor system, visit:

●

Latest

generation Aircore EC Product Page

●

Aircore

EC Motor Selection Tool

●

Infinitum

Sustainability Video

●

Blog